HVAC Capacitor Replacement

Capacitor Failures In Phoenix AZ

The harsh climate of Phoenix Arizona can strain HVAC equipment more so than other parts of the country. Your Air Conditioners capacitor is one of the most common components to fail. CTS Air Conditioning replaces dozens of capacitors throughout Maricopa county Arizona every year. If you think you have a bad capacitor on your HVAC unit, we can help.

CTS Air Conditioning provides the following service

- Capacitor diagnostics and testing

- Capacitor replacement

- New AC Capacitors

About HVAC Capacitors

Your HVAC systems capacitor usually looks like a small round or oval shaped metallic cylinder. Many air conditioners have 2 types of capacitors, a start capacitor and a run capacitor. Capacitors are rated in micro farads which are usually abbreviated uf or MFD. You should always replace a capacitor with one that has the same voltage and micro farad rating. In a typical residential air conditioning system the run capacitor is usually the one that is the lower micro farad rating and the start capacitor has a higher rating. A capacitor stores electrical energy and they should be discharged prior to handling or you could receive an electrical shock.

Serious injury or death can occur when working with electricity. Before touching anything inside the cover of your heating and cooling equipment, know exactly what you are doing.

What Is A Capacitor

Capacitors store electrical energy and release it to the motor it’s connected to. Be very cautious handeling them because they can store high voltage and will maintain their voltage even when the power to the AC unit is turned off. Most motors in an air conditioner need a capacitor to run.

Start Capacitors

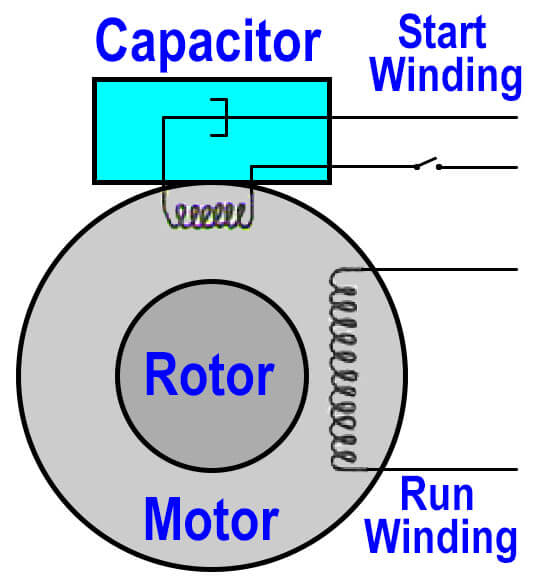

Start capacitors are typically used for air conditioner compressors and only to start the compressor. Once the compressor motor reaches 60% to 75% of it’s full speed a relay opens to disconnect the start capacitor from the electrical system. It must be disconnected from the circuit or damage to the motor winding will occur. The single phase induction motor typically found in HVAC compressors needs extra starting torque to begin operation. The start capacitor accomplishes this by splitting the phase of electricity into a second coil of wire in the motor called the start windings. The start windings give the motor lots of starting torque when they are engaged. After the motor is spinning fast enough a relay disengages the start winding and start capacitor from the electrical circuit.

Run Capacitors

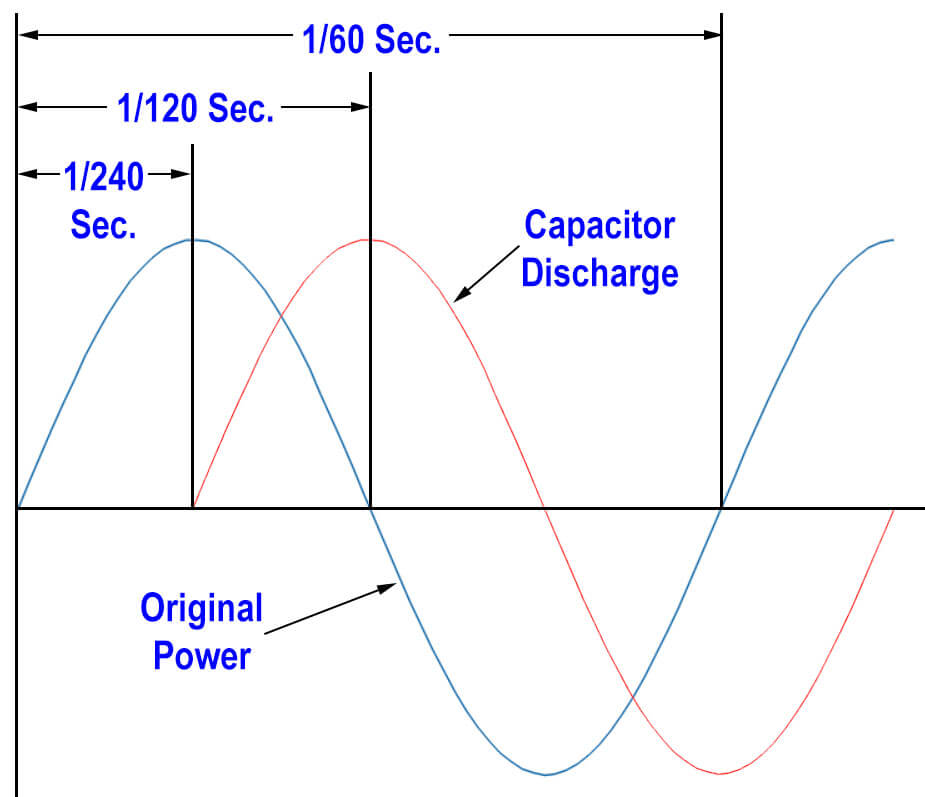

Run capacitors are often found on single phase induction motors used in blower motors, condenser fan motors and AC compressors. They are used in heat pumps as well as air handlers found in most residential air conditioning systems in the Phoenix area. The run capacitor charges as the voltage as a given AC cycle increases in voltage. When the voltage begins to decrease the run capacitor releases it’s energy to the motor. Run capacitors create a phase shift which greatly improves the efficency of the motor. Run capacitors are designed to dissipate heat, never use a start capacitor in a run capacitor circuit. Run capacitors greatly improve the efficiency of an HVAC system by improving the power factor. Run capacitors are always in the electrical system during operation and are not disconnected like run capacitors are.

Why Do HVAC Capacitors Fail?

In time almost everything will break down and stop working simply due to age. HVAC capacitors are no exception. Due to constantly storing and releasing electrical energy, eventually capacitors will wear out and go bad. The exteeme heat experienced in Phoenix Arizona and the Maricopa County area can dramatically shorten the life of an HVAC capacitor. Higher demand on an HVAC system in conjunction with higher temperatures can overheat components like capacitors and make them fail. When the monsoons season starts, power surges caused by electrical storms can also take out your HVAC system’s capacitor.

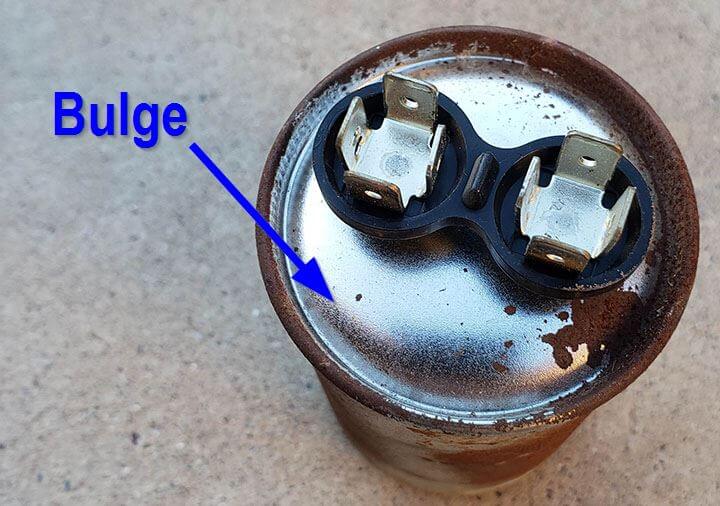

Electrolytic capacitors are especially sensitive to heat. High temperatures can cause electrolyte evaporation. Leakage current through the capacitor will also generate heat due to power loss. Leakage current can happen after long periods of storage as aluminum oxide can start to disolve in the electrolyte.

When the electrolyte vapor pressure increases, the seal of the capacitor will bulge. This is a telling sign that the capacitor has experience some type of thermal failure.

Replacing HVAC Capacitors

One of the signs that your air conditioners capacitor is starting to go bad is high current draw. Other signs of a failing capacitor are bulges in the package or an oil leak.

A common symptom of a bad HVAC capacitor is loud humming noises from the A/C condensing unit. If you push the condensing fan with a stick and the unit starts running, it’s most likely a bad capacitor.

To test a capacitor, use a capacitance meter. Before disconnecting the capacitor make notes of which wires are connected to which terminals on the capacitor. The micro farads measured should be within 10% of the rated value. If you don’t have test equipment a simple alternative test is to substitute a good capacitor in place of the one that you want to test. If the motor starts to operate then the old capacitor is bad.

How to replace an HVAC Capacitor

If you have found that the capacitor on your air conditioning unit is measuring out of tolerance and my soon fail then it should be replaced. Here is a guide for how to replace a failing HVAC capacitor:

- Turn off to the HVAC unit.

Turn off the circuit breaker that controls your air conditioner or break power at the disconnect box. - Open the access panel and locate the capacitor.

Inspect and test the capacitor to see if it’s causing the problem. - Write down the capacitor’s capacitance and voltage rating.

Try to replace the capacitor with one that has the same ratings. If you can’t find an exact match, it’s better to choose a new part with a higher voltage and capacitance rating over a lower rating. Don’t exceed 10% of the original capacitance value. - Discharge and disconnect the capacitor.

Before disconnecting it’s a good idea to lable the wires or take a picture to make sure the new capacitor is connected to the correct terminals. - Install the new capacitor.

Mount the new capacitor in place of the old one and connect the wires to the correct terminals. - Turn the power back on and test.

If your AC unit still doesn’t work, turn power back off, discharge the capacitor and verity the wires to the capacitor were installed correctly.

Troubleshooting HVAC Capacitors

The video below has some great advice about troubleshooting and replacing HVAC capacitors.

How Much Does An HVAC Capacitor Cost

The capacitor in a typical residential HVAC unit in Maricopa County, Arizona is reasonably inexpensive. When purchasing a new capacitor pay attention to the voltage rating and micro-farads of your current capacitor. Try to get an exact match to the original component. Pay more attention to the voltage and capacitance ratings than the size and shape of the part. A capacitor for a residential air conditioner such as Trane, Goodman, Carrier, Rheem, York, etc. costs between $35 to $75 in most cases for the part. HVAC companies will charge somewhere between $150 to $300 to replace it depending on the job. If you would rather not do this yourself, CTS Air Conditioning is ready 24/7 to service your HVAC needs with fast service and excellent prices.